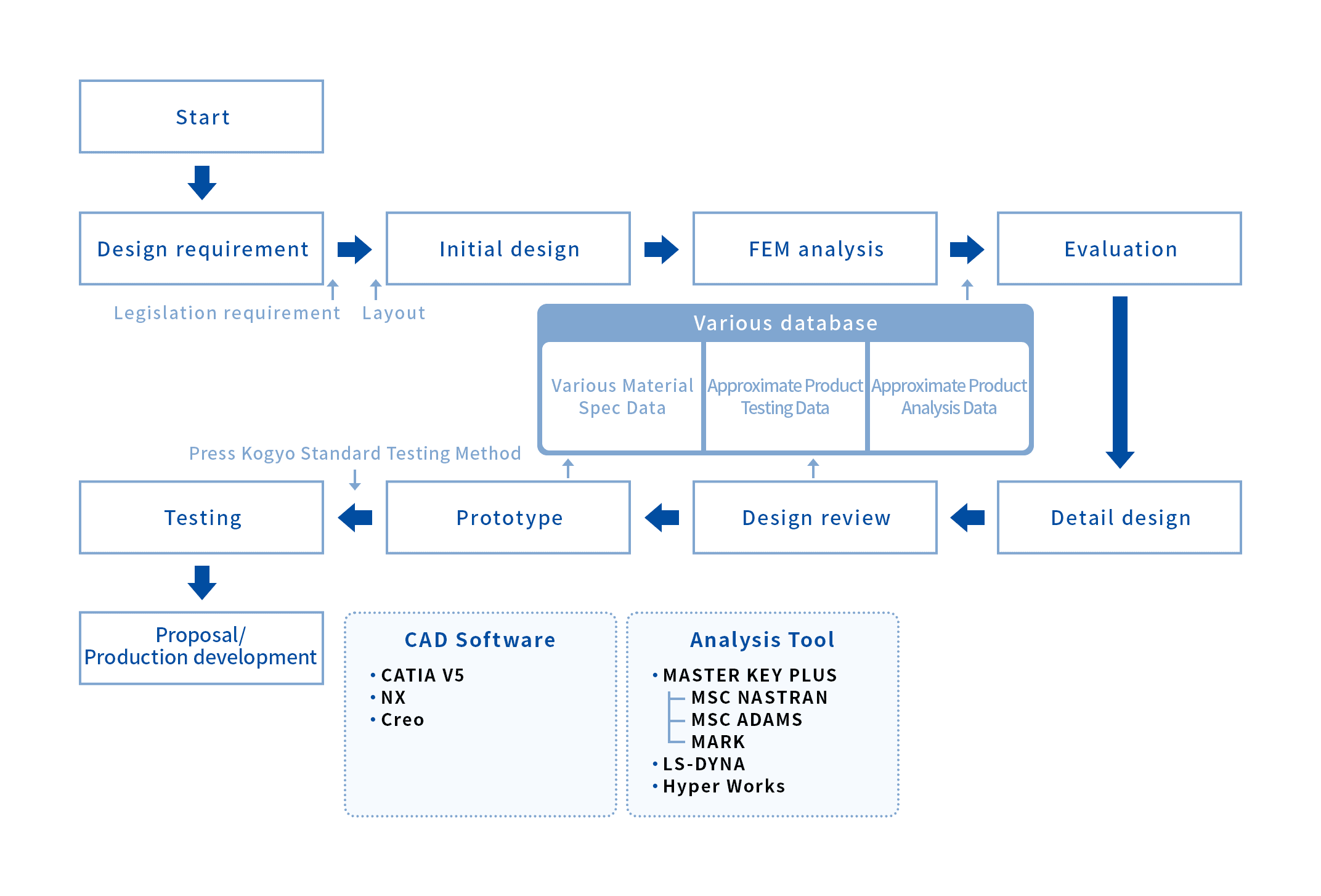

Development Process

Development Process

CAE / Machine Testing

For efficient product development, Press Kogyo frequently evaluates products prior to prototyping. We use computer-aided engineering (CAE) in such areas as metal forming simulations to assess formability as well as strength analysis to assess product performance. Products evaluated in this way are given a final assessment using production machinery to provide peace of mind to customers.

Based on these evaluation technologies, we have developed many forming technologies such as processing technology for variant shaped steel pipes that use special technology, paper folding form (PFF) techniques for bending steel sheets like paper when creating products, and precision press operations.

We will continue to develop competitive products by improving and enhancing our evaluation technologies according to their purpose.

Metal forming simulations

Formability is assessed through metal forming simulations after creating the design model.

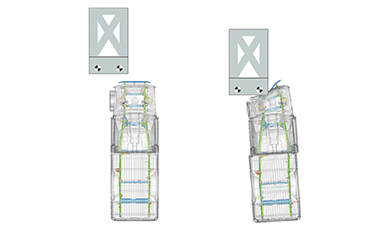

Strength Analysis

We use strength analysis to check whether the product being developed meets design requirements. In addition, we make assessments based on various analyses, depending on the purpose, including collision and multibody dynamics analysis.

Actual vehicle running

Reproduction of road simulator running

Axle strength analysis

Visualization of offset collision

Frame collision analysis

Bench Test

Products evaluated using CAE will ultimately be evaluated using prototypes to verify performance and determine compliance with design requirements. Further, data acquired is feed back into the analysis while the test products are analyzed, and the findings are reflected in the development of future products.