Creating a Safe and Secure Workplace

Occupational health and safety

Basic Safety and Health Policy

Basic Philosophy

『Safety and Health』 takes precedence over everything else.

Basic Policy

We will continuously improve our safety and health management system under the following basic policies, maintain good communication between labor and management, and promote safety and health activities in unison.

We aim to develop safety-conscious people and workplaces that will absolutely prevent serious occupational accidents.

We will steadily operate the safety and health management system, continuously improve the management level of people, machinery, working environment to strengthen the mechanism to prevent serious occupational accidents.

We will build a workplace where rules are followed and enforced so everyone can work safely and with peace of mind.

We will remain a trusted company in society by abiding by all safety and health-related commitments, including the Labor Safety and Health Act..

We will strive to prevent occupational accidents by identifying potential dangers and hazards.

We will work to eliminate hazard sources and reduce safety and health risks through risk assessments.

We will promote a work environment that emphasizes wellbeing and comfort.

We will promote the creation of a workplace environment where each and every employee can take an interest in their health and work energetically both physically and mentally and provide support health promotion.

We will set, implement and evaluate goals when carrying out the policy, additionally, enhance the content by reviewing as appropriate.

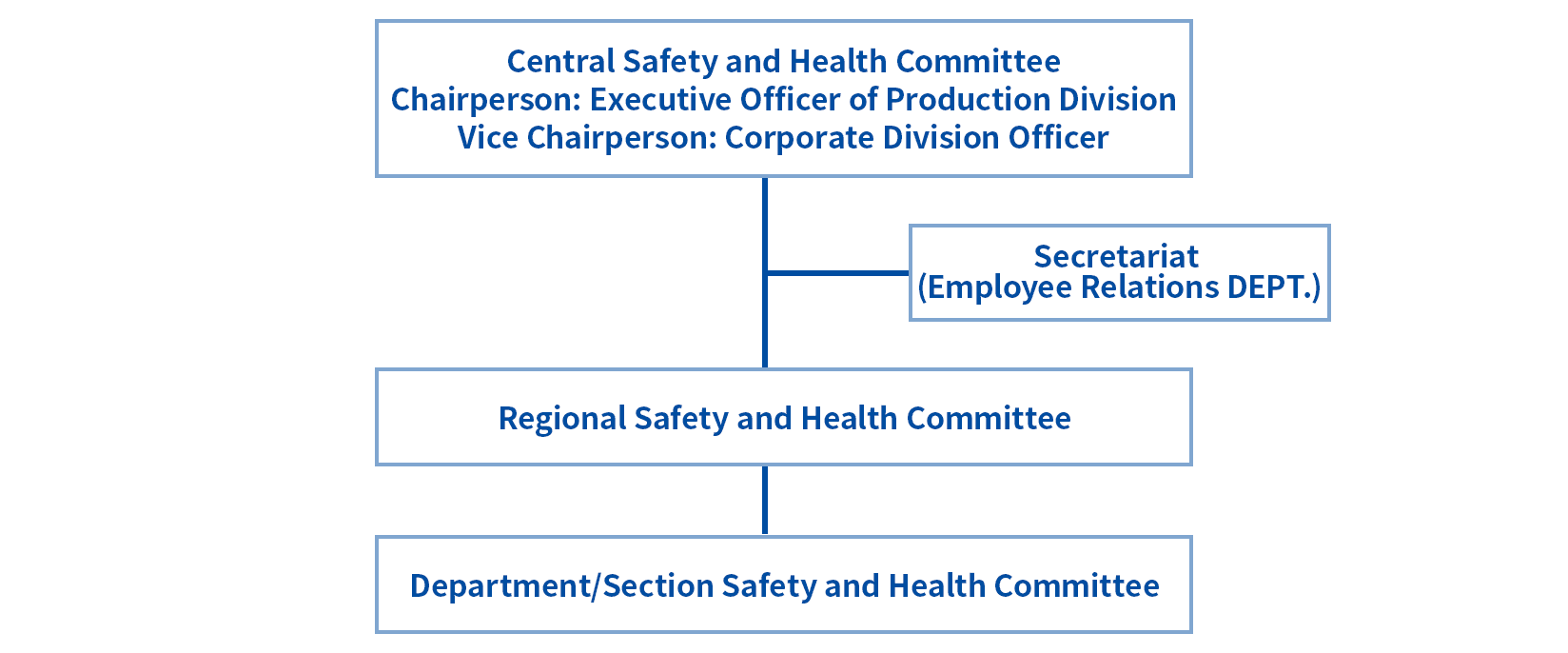

Promotion System

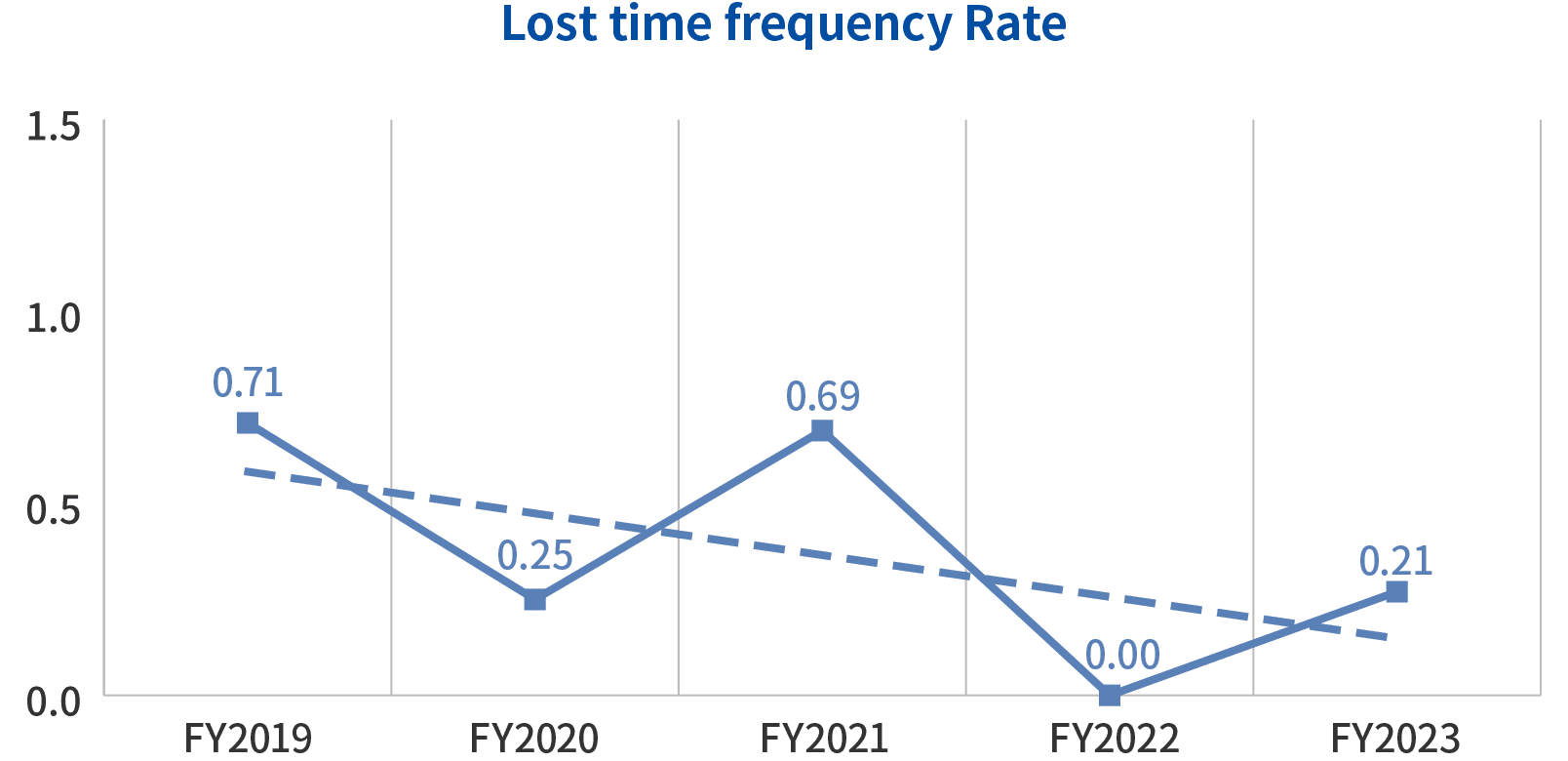

Indicators of safety and health

Lost time frequency Rate

Lost time frequency rate = (number of deaths and injuries / total number of actual working hours) x 1,000,000

Promotion of risk assessment and risk reduction measures

Through risk assessment, we identify and evaluate hazard sources, and work to eliminate or mitigate them according to the risk level. We inform and educate workers about the processes leading to residual risk hazards and their severity.

Education on residual risks

Safety Education

We define "safety-conscious person" as 『someone who can follow work procedures, exercise risk prediction, and can “stop, call and wait” when an abnormality occurs』, and we are working on developing such human capital.

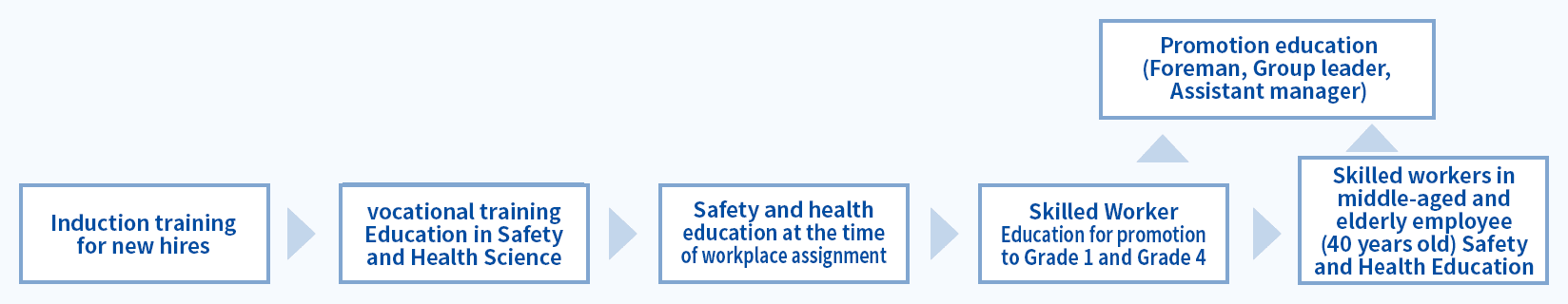

1.Education system

Regarding safety and health, we mainly provide the following education tailored to each hierarchical level.

The following is a general education system in the case of enrolling a technical school as a skilled worker.

2.Experiential training

We conduct experiential training according to workplace risks to enhance risk sensitivity.

By operating the machine with residual air pressure and crushing an empty can, we recreated a pinching accident.

Drop a training dummy from a height to simulate the impact of a fall.

3.Safety meeting

We hold a monthly safety meeting at each workplace to promote communication and raise safety awareness.

Safety Excellence Commendation System

We aim to enhance the motivation for improvement and share good practices by commending workplaces and small groups that have achieved effective improvements in preventing disasters.

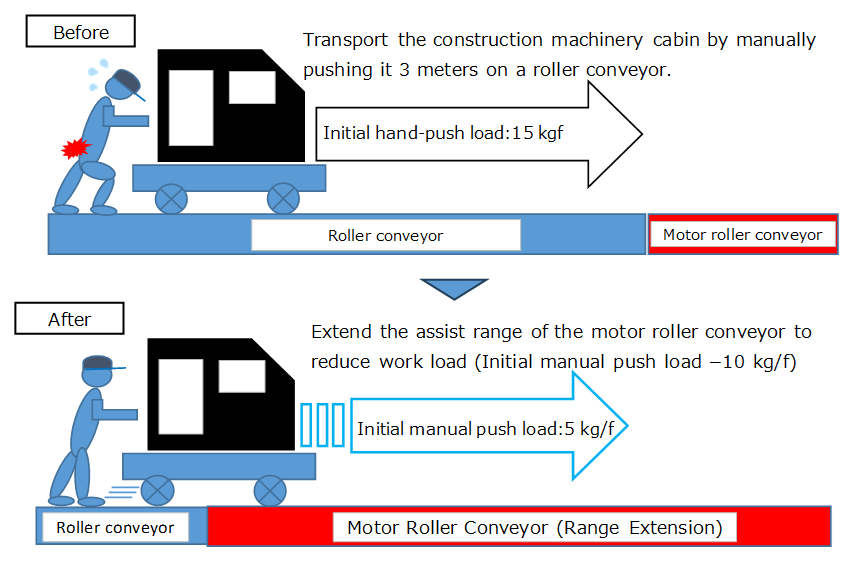

Power rollers were added to the inter-process transport rollers

for construction machinery cabs to reduce the burden of manual pushing.

Age-friendly

Age-friendly initiatives are viewed not only for the senior generation, but also as "creating a workplace environment where anyone can work comfortably." We set a theme every year, identify risks, and work to make improvements.

Improving Difficult and Advanced Tasks

We identify “difficult and advanced tasks” such as handling heavy objects, working in awkward postures, and tasks requiring advanced skills or knowledge. By improving these tasks, we contribute to creating a safe and comfortable workplace environment.

Improvement Examples

By eliminating the step on the work surface and making it flat, the workload when moving parts has been reduced.

Safety and Health Activity Review

The chairperson of the Central Safety and Health Committee reviews the priority measures for safety and health policies.

Additionally, both labor and management confirm, evaluate and improve the performances and on-site activities of our 5 domestic plants and affiliates.

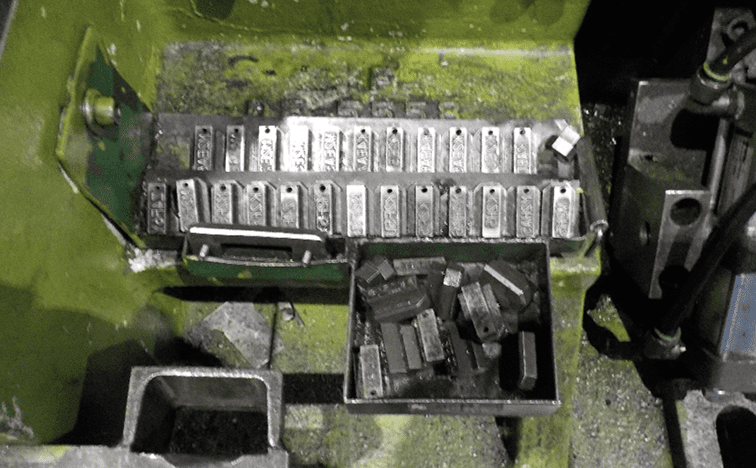

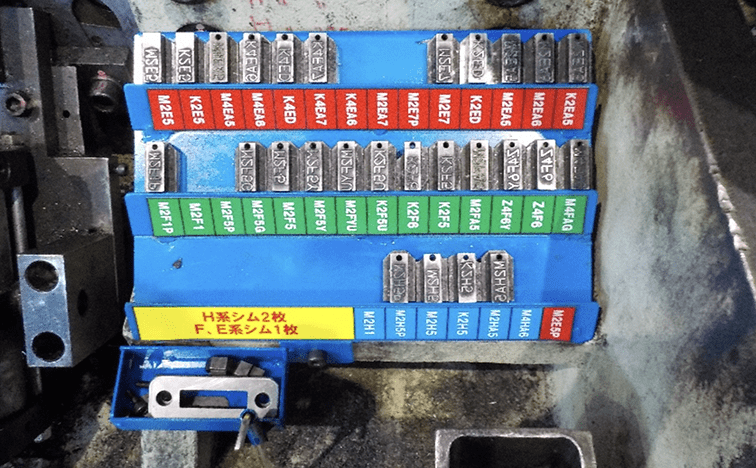

5S Activities

We are working to ensure safety, improve quality, and eliminate waste and inefficiencies by promoting 5S activities.

We are also committed to training "5S Masters" who will promote the 5S activity PDCA cycle to revitalize 5S activities.

We improved the practice of placing items on the floor by organizing and creating shelves.We used photos for signage so that even those unfamiliar with Japanese could understand the designated placement and items.

5S Master Certification System for those recognized to have a certain level of competence