Plastic Parts

What's Plastic Parts

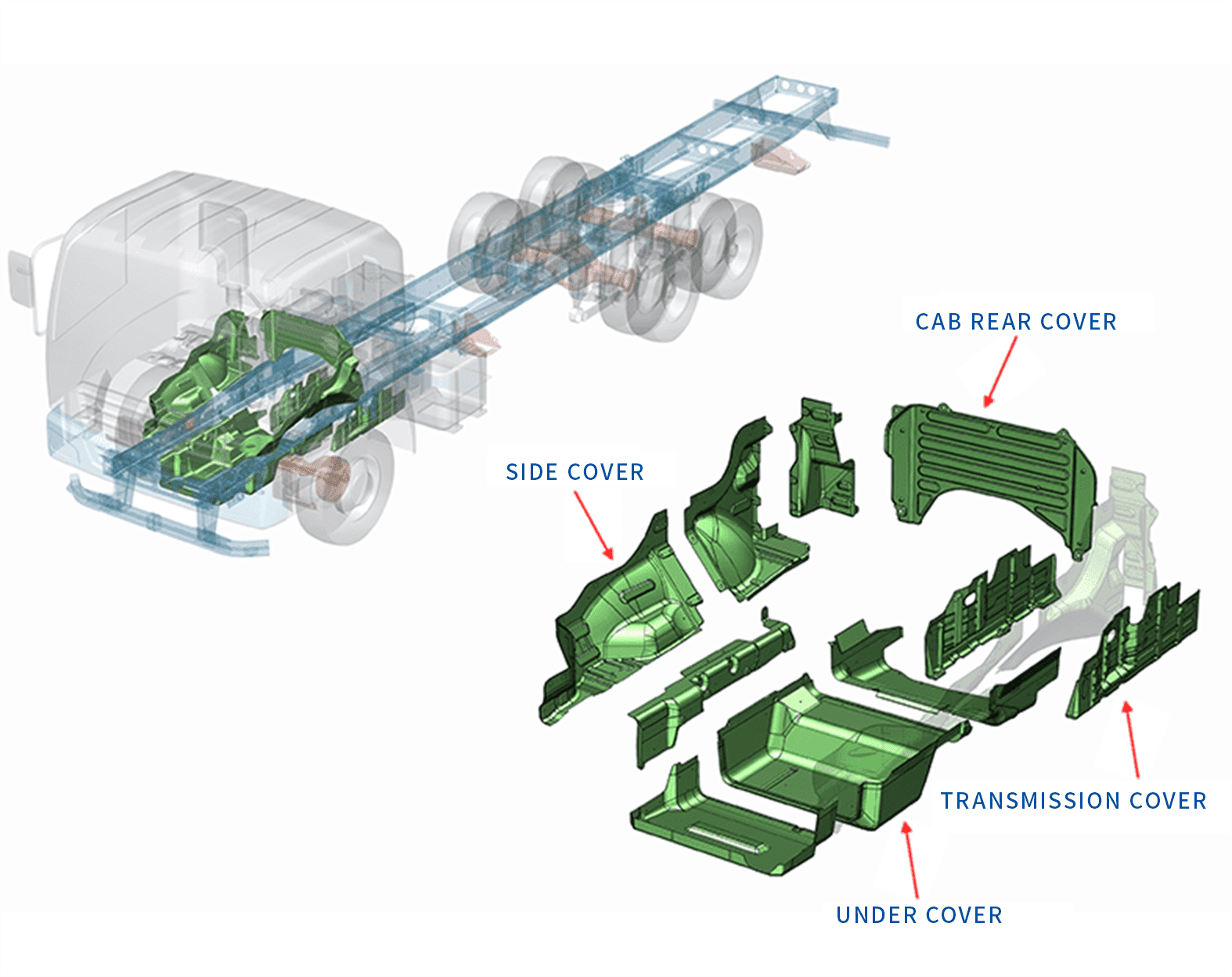

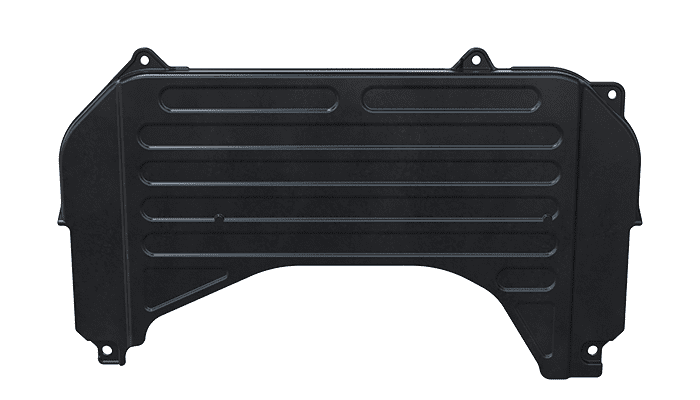

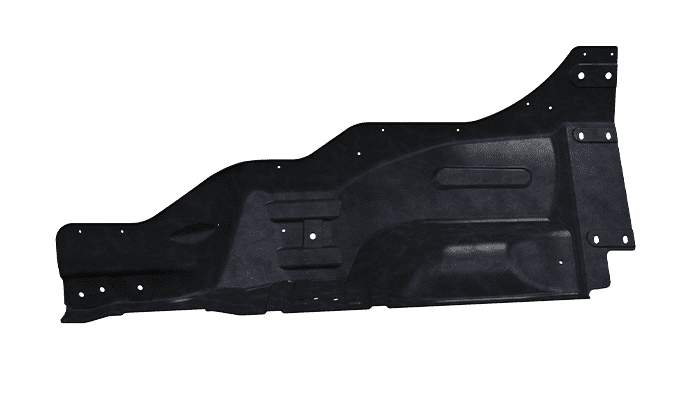

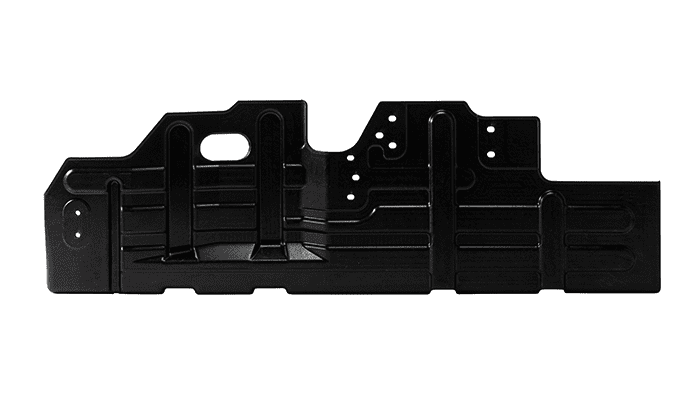

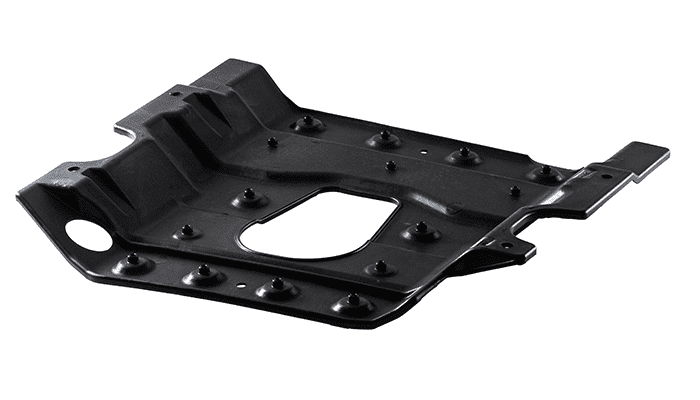

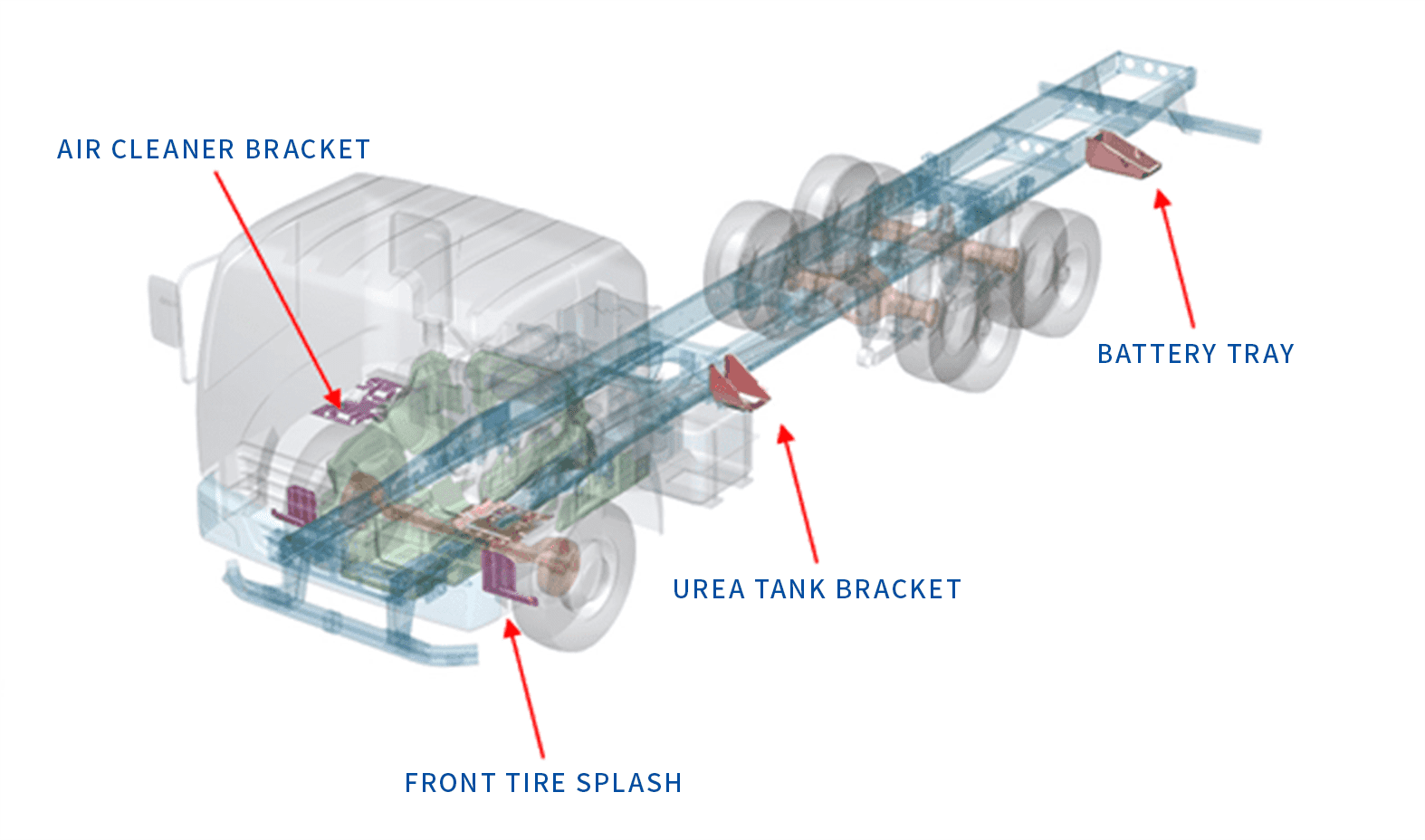

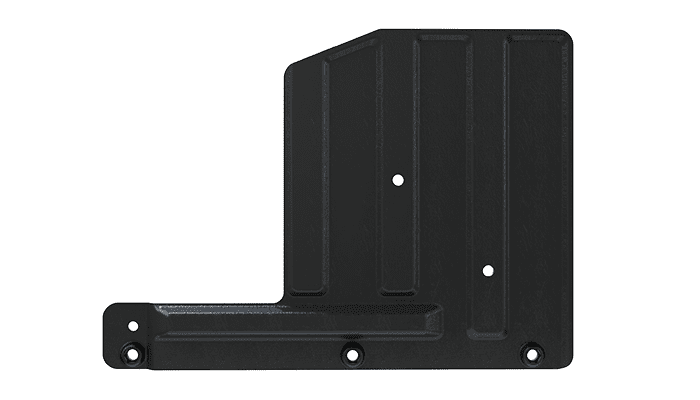

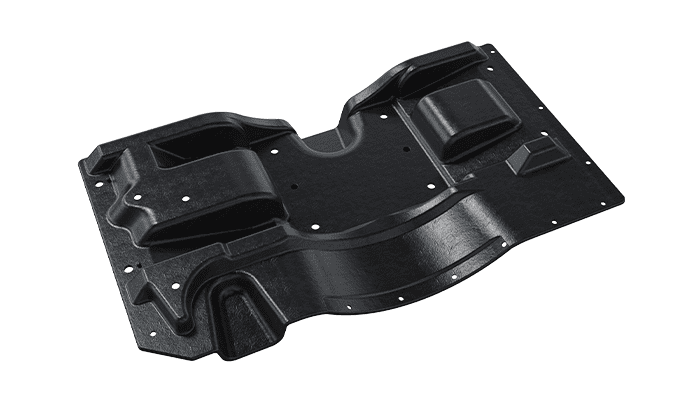

We have continued to propose the replacement of steel products with resin to meet the demand for lighter vehicles. Our primary resin product is known as a stampable sheet, a mixture of thermoplastic resin (polypropylene) and glass fiber, which provides exceptional strength and rigidity. We capitalize on these characteristics to manufacture other products as well, predominantly engine sound insulation covers (acoustic shield), that we deliver to truck manufacturers.

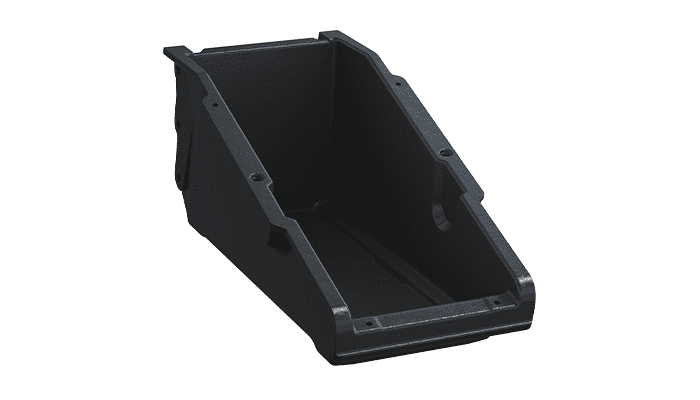

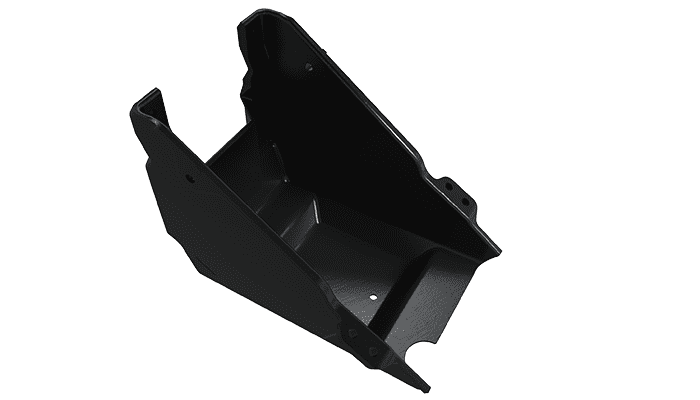

We manufacture various injection molded products from large to small.

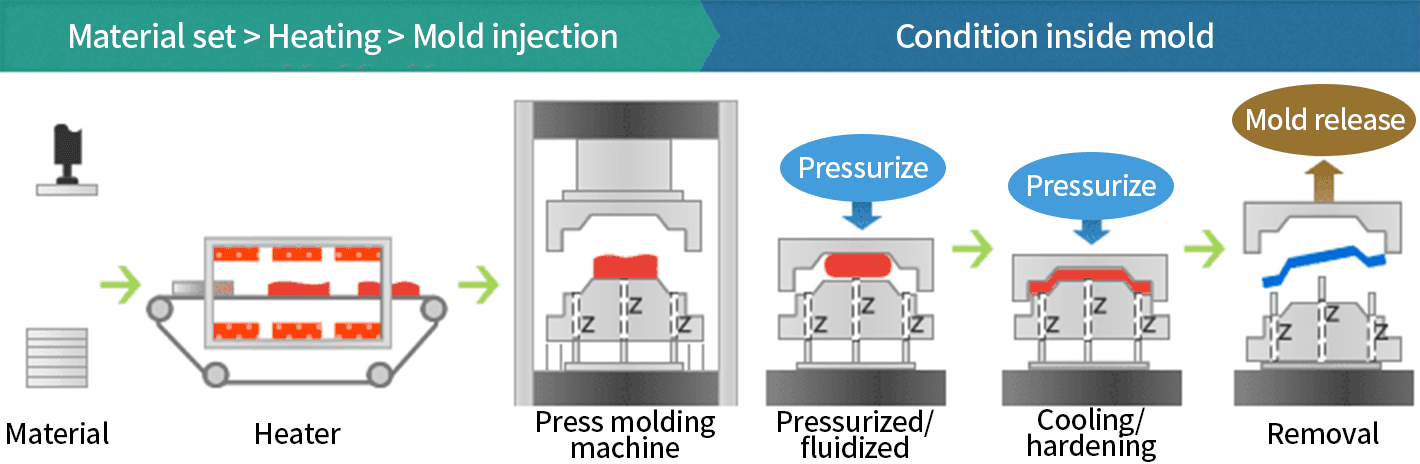

Stampable sheet production process

The production process for stampable sheets involves heating material cut into sheets with a heater to give it plasticity, adding pressure with a pressing machine, and then removing the cured, formed product from the die. The formed products are called stampable sheet product.

Since glass fiber retains its properties even after forming, it is possible to produce a tough product due to the content and orientation of the glass fibers. The strength and rigidity of the sheets can also be controlled.