Chassis Frame

What's frame

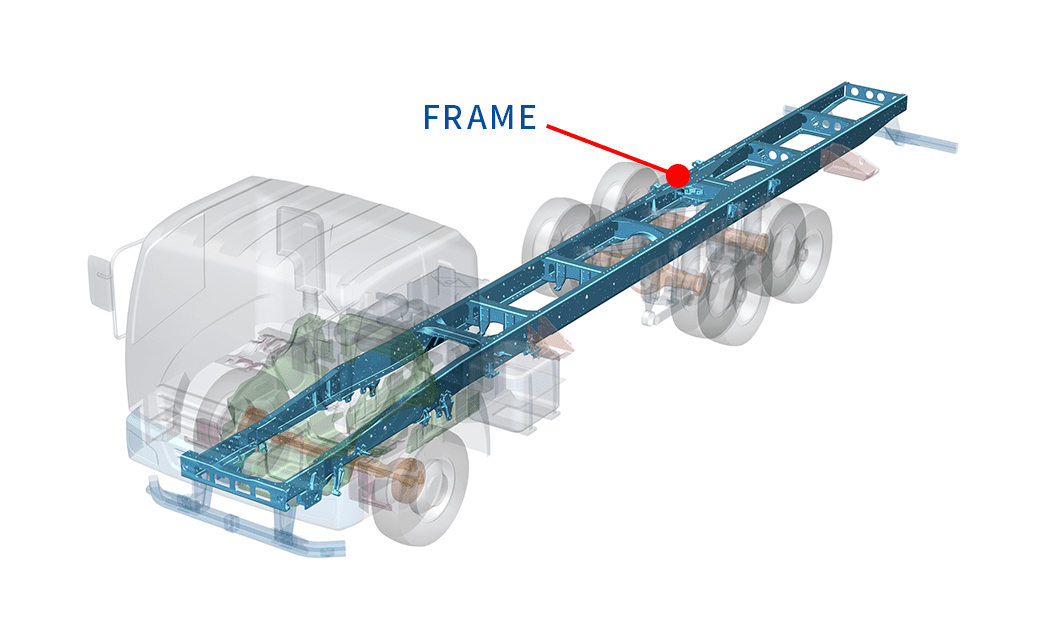

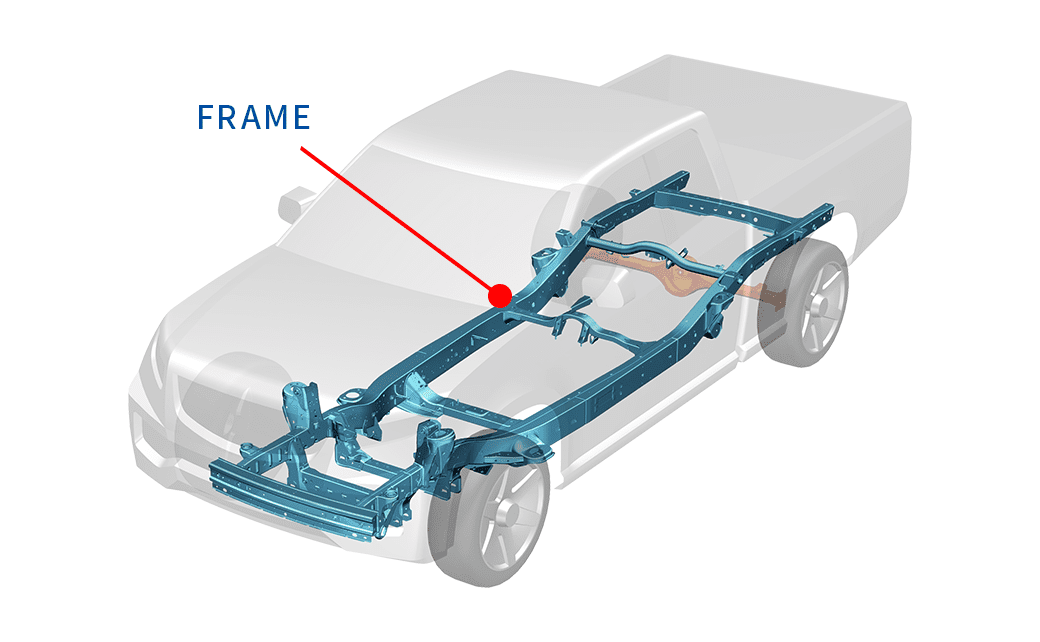

A frame is a product, which could be called the truck’s skeleton, that supports the full weight of the vehicle, and is mainly made of parts pressed out of steel plates. There are wide varied specifications to respond to vehicle variations, with overall length of the short frame being approximately 4.5 m for light trucks and pickups, and the long frame being 12 m for heavy trucks.

Truck

Can be viewed in 360°

Pickup Truck

Can be viewed in 360°

Function

Frames not only support cargo but have the functions of receiving the road load through a suspension, and being equipped with engine and drivetrain, such as a cab (driver’s seat), as well as accessories, such as a refrigeration unit and a mixer.

Furthermore, a wide range of matters are requested, such as ensuring rigidity to improve running stability and ride comfort, and weight reduction to increase cargo capacity.

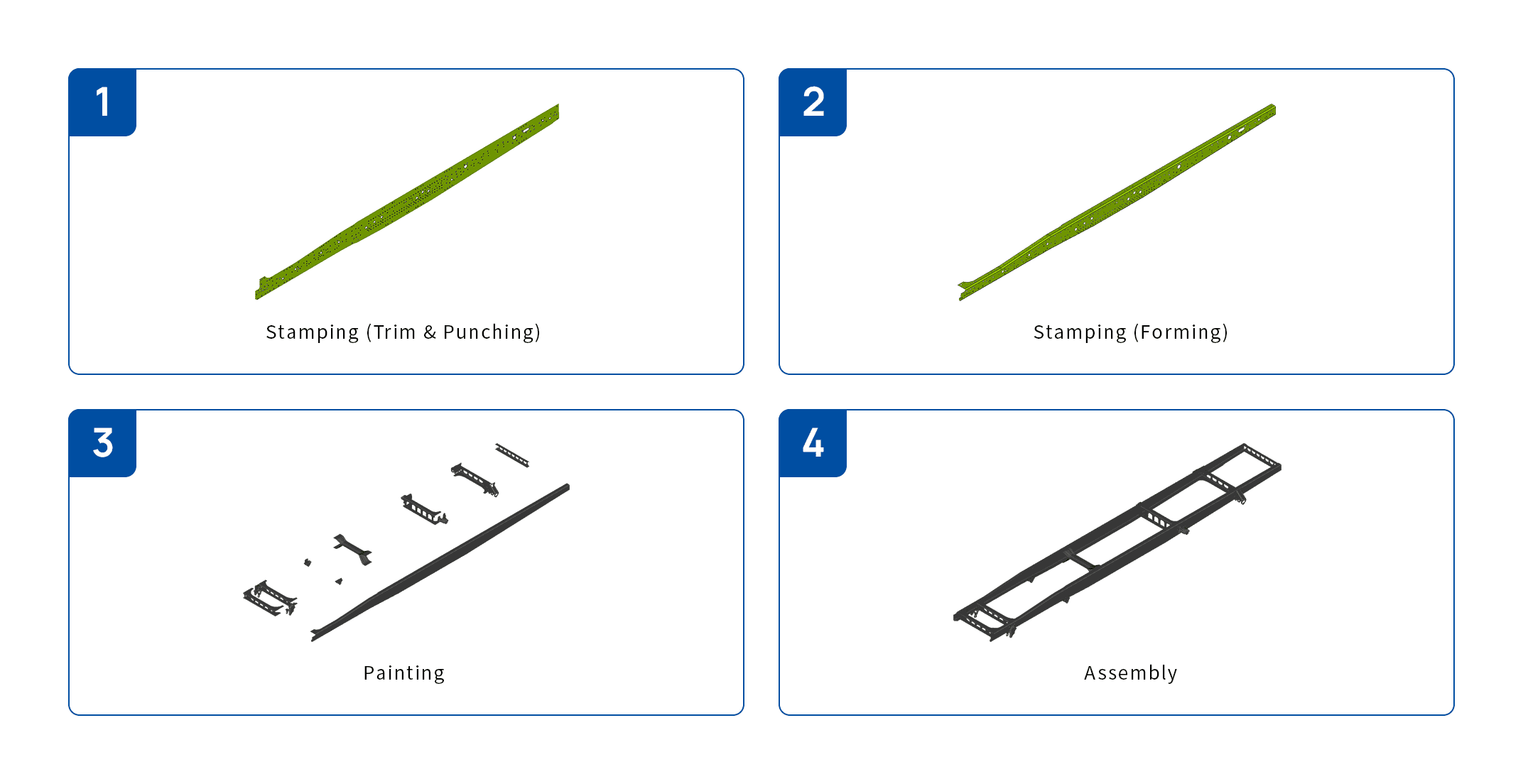

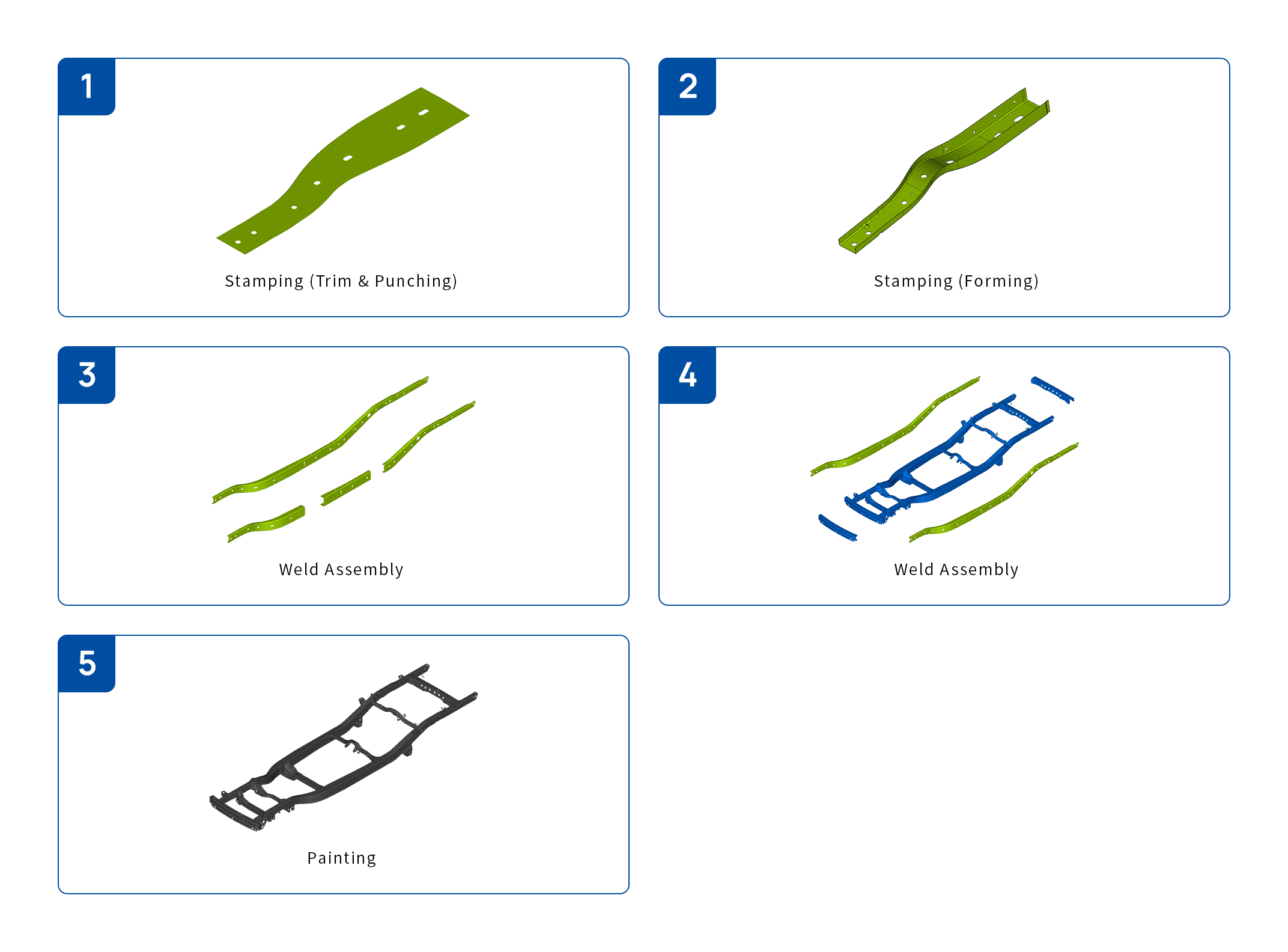

Production Process

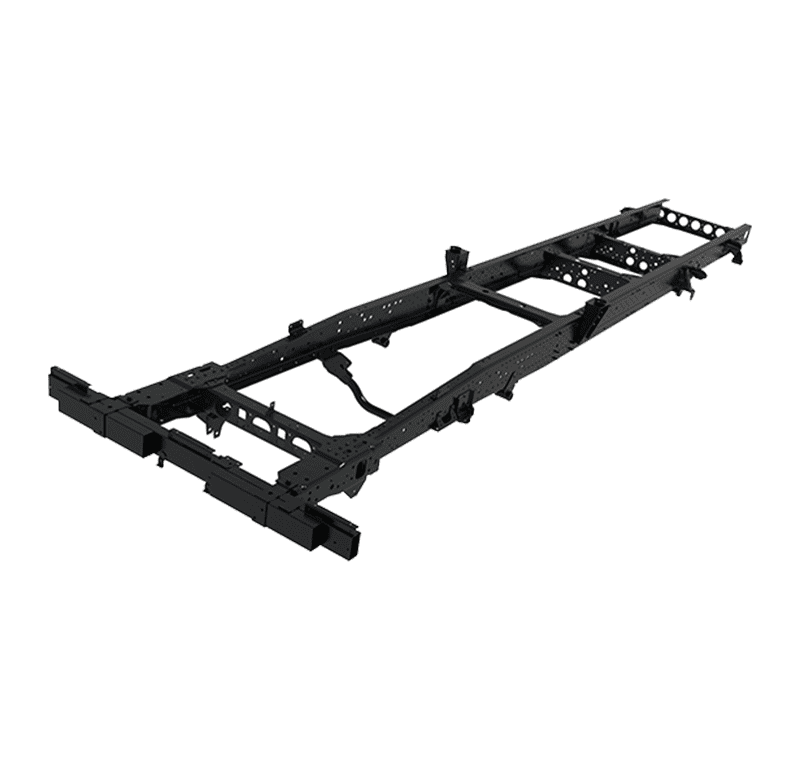

Light duty truck

Heavy & medium duty truck

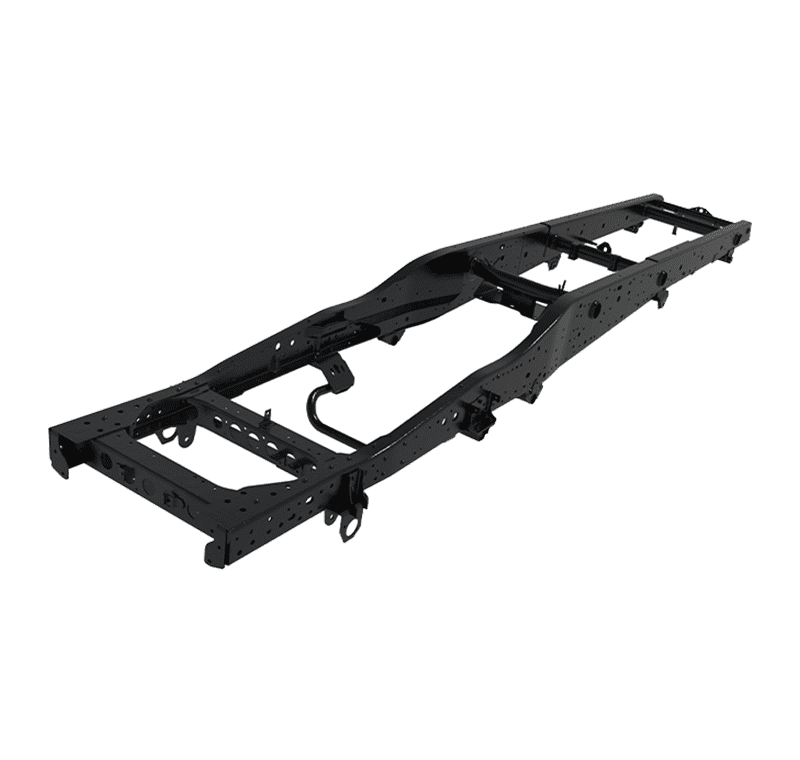

Pickup Truck & SUV

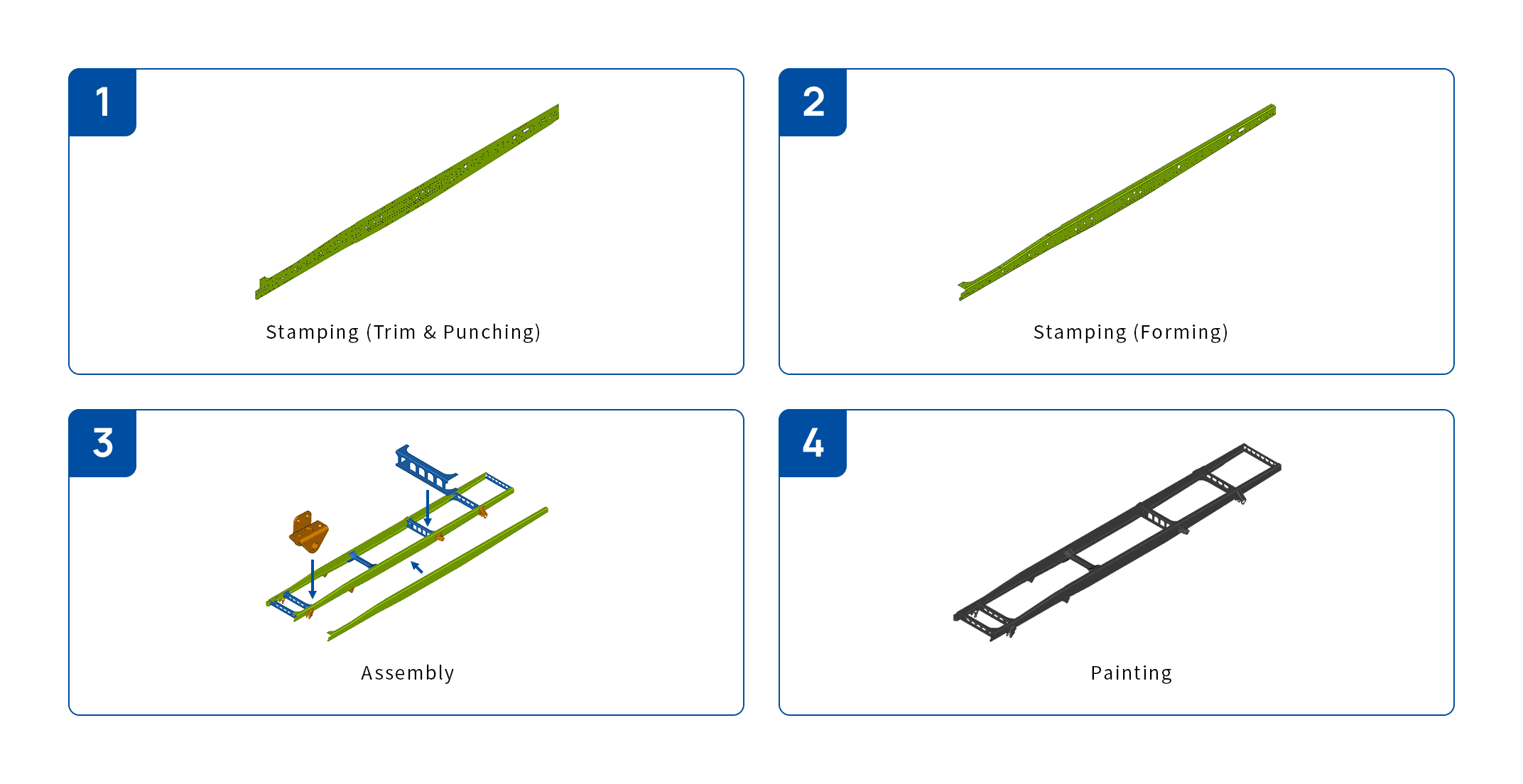

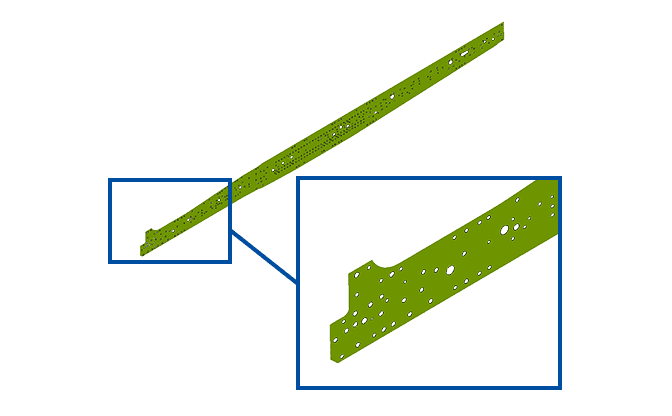

①Stamping (cutting and piercing)

For side members, first the cutting and piercing are made using a steel plate with a maximum thickness of 10 mm and maximum length of 12 m that is processed using a NC-pierced machine or a cut-pierced die.

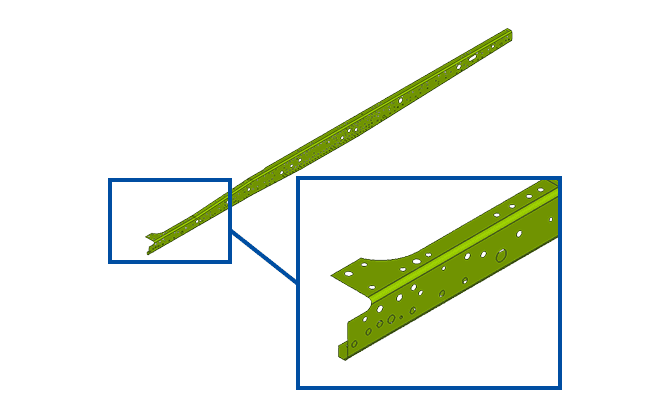

②Stamping (forming) / offset processing

After completing the cutting and piercing, for heavy and medium-duty trucks, the steel plate is pressed into a U-shape using one of the world's largest 5,000-ton presses. An offset bender helps to create a variety of side member shapes.

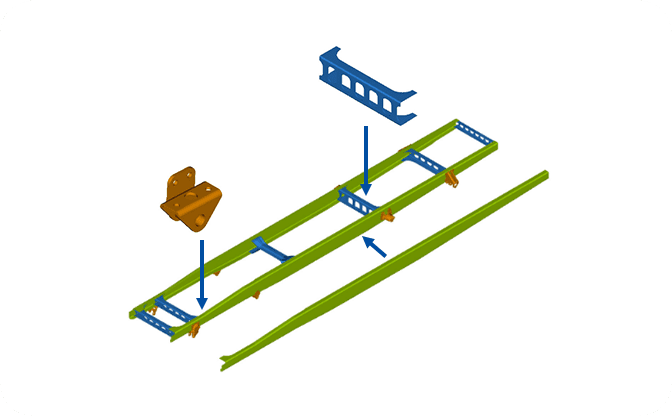

③Assembly

The left and right side members and multiple cross-members are assembled into a ladder structure and the components are fastened together, mainly using rivets and bolts.

Video:Weld Frame Automation Line④Coating

The frame for light duty trucks is painted after assembly, the frame for medium and heavy duty trucks are painted as parts.

The surface of the steel plates can also be treated through blasting.

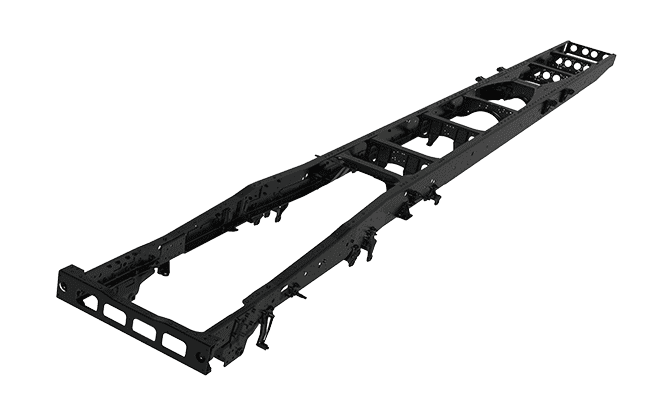

Frame Type

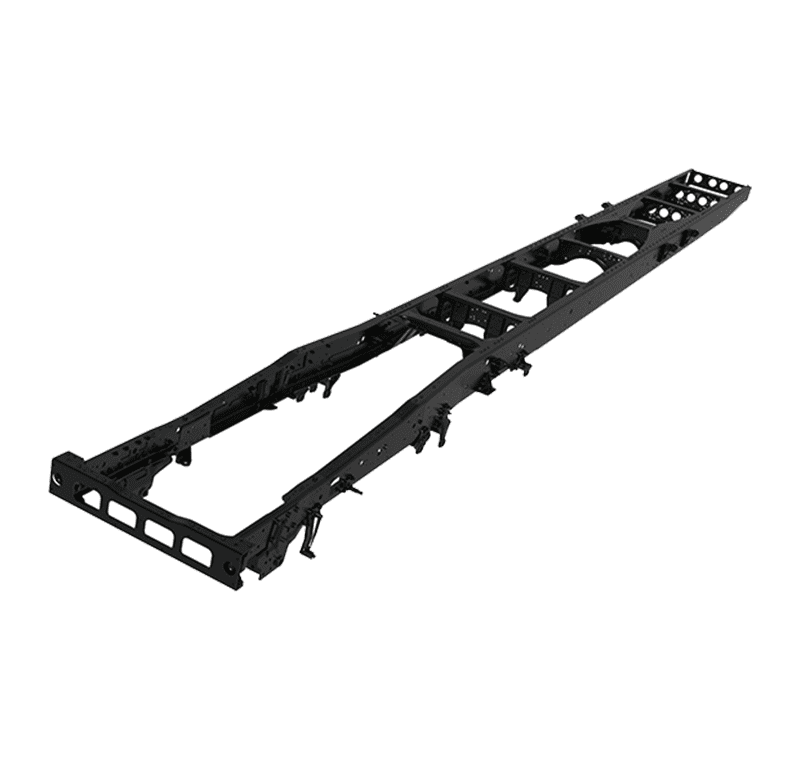

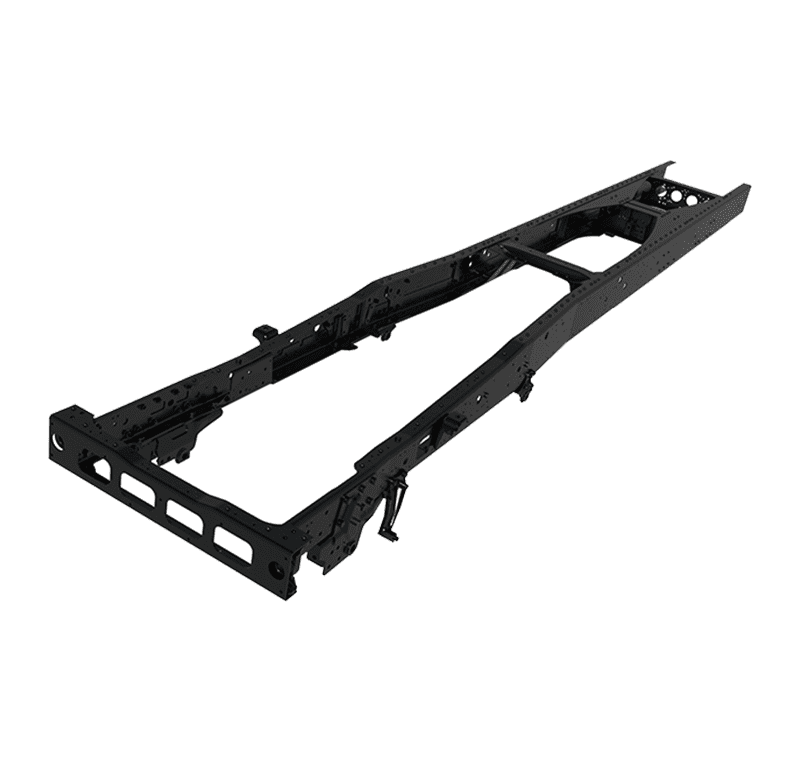

Rivet Frame for Heavy Duty Truck

Rivet Frame for Medium Duty Truck

Length=5.1-11.7m

Wide=0.84-0.87m

Mass=230-1,170kg

Rivet Frame for Light Duty Truck

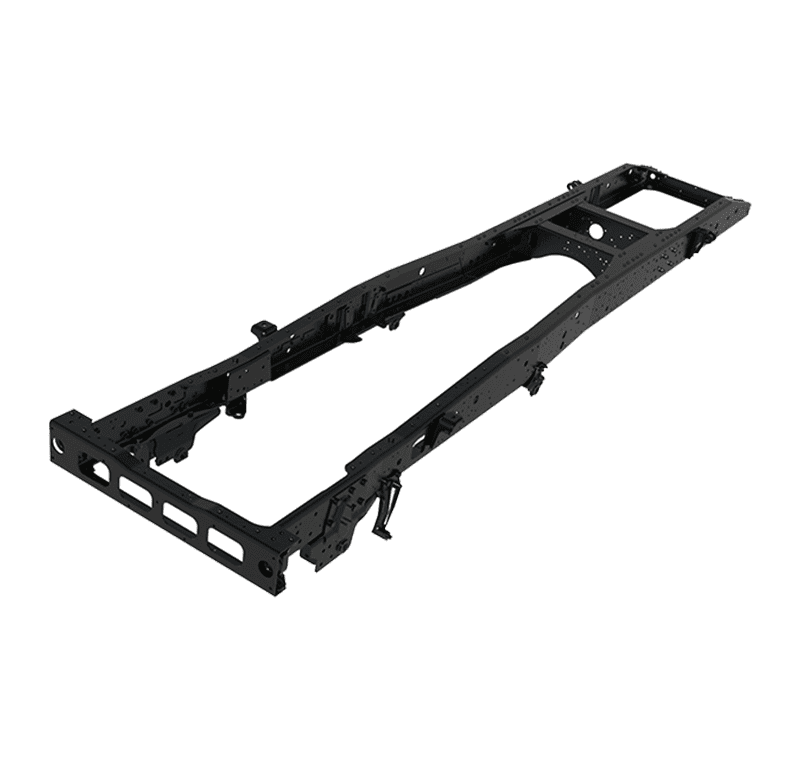

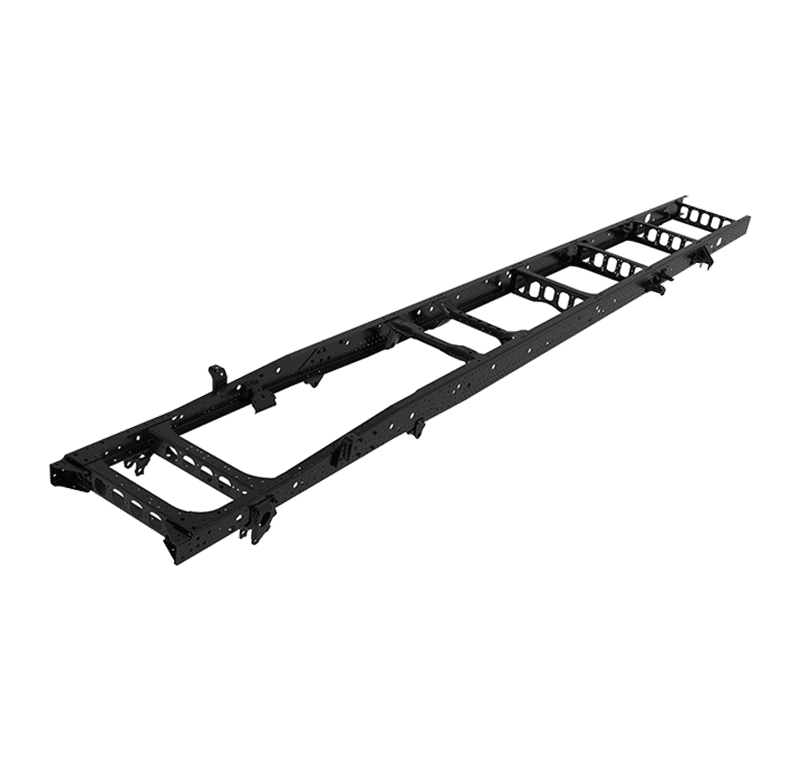

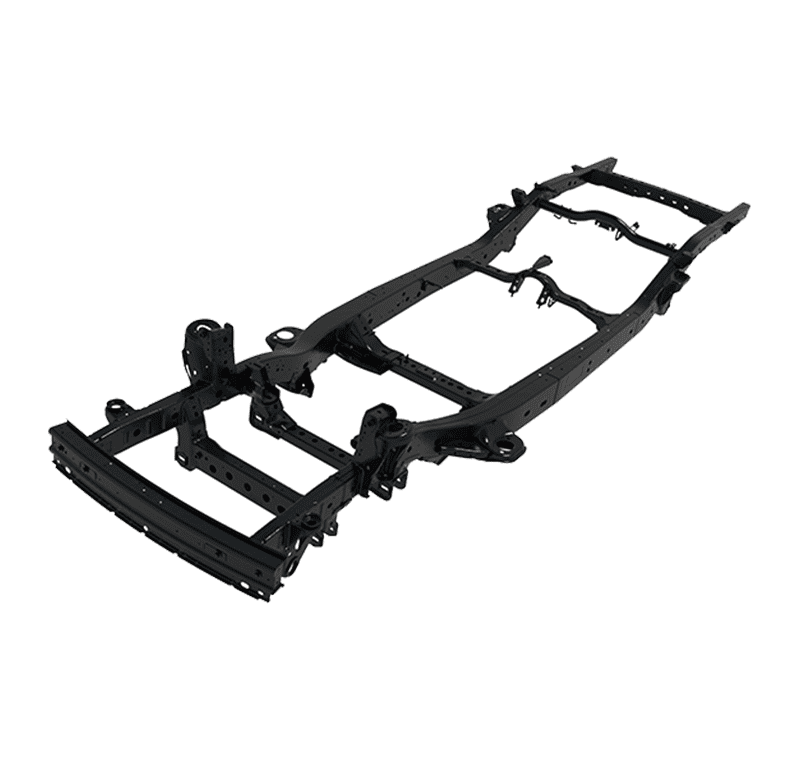

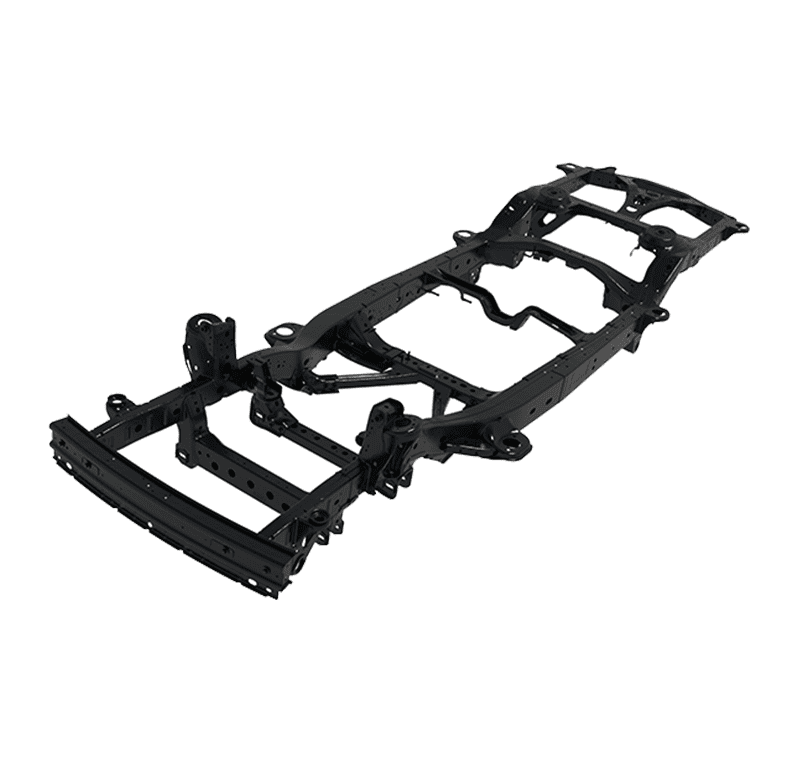

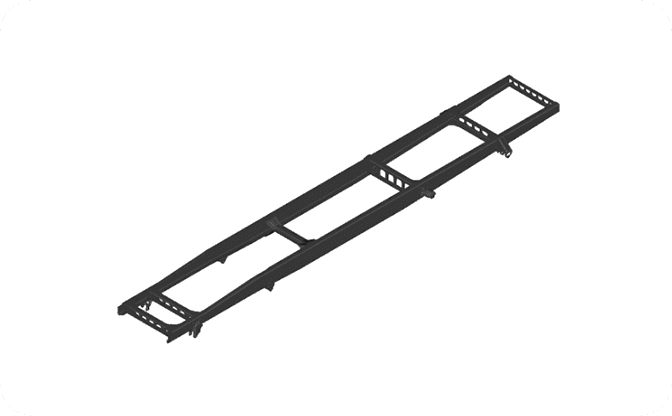

Weld Frame for Pickup Truck & SUV

Length=4.5-5.1m

Wide=1.4m

Mass=189-252kg