1975

Ground-breaking ceremony held for Utsunomiya Plant

A press-dedicated plant to supply pressed parts to other facilities was planned, and factory land was acquired in the Nishitsuboyama Industrial Park, Kawachi District, Tochigi Prefecture.

1976

Utsunomiya Plant commenced operations

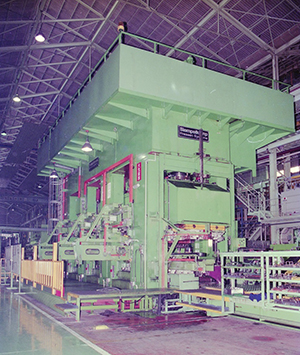

Phase 1 construction was completed, and a completion ceremony was held. Operations began with a 5,000-ton rail press manufactured by Siempelkamp in West Germany and NC-piercing machine manufactured by Betty.

1986

Installed 2,000-ton transfer press and 800-ton blanking press

Started production of axle case side plates for light-duty trucks.

1986

Installed 4,500-ton press from Siempelkamp

This enabled integrated press processing of axle case side plates for light-duty to heavy-duty trucks.

1987

Installed 500-ton blanking press and heating furnace

Began hot press processing of axle cases sides plate for heavy-duty trucks.

1988

Cationic coating line for side members commenced operations

Introduced a fully automated coating line synchronized with press operations, significantly enhancing corrosion resistance of side members. In June, NC-piercing machine was added.

1992

Installed second 5,000-ton rail press from Siempelkamp

Improved workability by enhancing press speed compared to the first machine.

1995

Picking yard for side members completed

Enabled sequential delivery of side members to each plant.

1999

Tochigi Plant closed and integrated into Utsunomiya Plant

Expanded the building and transferred the functions of the Tochigi Plant, which concluded its 26-year history.

1999

Transferred production of side frames for Volvo from Kawasaki Plant

2000

Acquired ISO 9001 certification

2003

Turret punch & laser processing machines commenced operations

2007

Completion ceremony held for new office building

2009

Started welding and machining production of axle cases for heavy-duty trucks for Hino Motors’

Received first order from Hino Motors for fabricated axle cases and began mass production.

2013

New axle case for heavy-duty press line commenced operations

Installed two 3,000-ton press machines and the latest heating furnace to improve product precision.

2016

Introduced air blasting process for side members

Introduced air blasting process to remove oxide film from side members, enhancing paint quality.

2018

Transferred side member drilling line from Kawasaki Plant

Transferred the drilling line for side members for Mitsubishi Fuso Truck and Bus from the Kawasaki Plant and started production.

2023

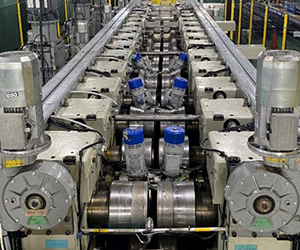

Installed roll forming machine for side members

To expand production options, a roll forming machine for side members was provisionally installed, along with a material feeding device.

2025

Commenced expansion work of Press building

Began expansion work on Press Building I to accommodate new production equipment.