1967

Ground-breaking ceremony held for Onomichi Plant

Acquired land in Takasu-cho, Onomichi City, Hiroshima Prefecture, to establish a manufacturing base in western Japan, and held a groundbreaking ceremony.

1968

Onomichi Plant commenced operations

In January, the plant building was completed and equipment such as die-matching machines and presses was installed in sequence. Operations commenced, and a ceremony was held on November 21 to commemorate the completion of Phase 1 construction.

1969

Started production of boxer frames, panels, and axle cases for Toyo Kogyo

Received orders for medium-duty truck parts and began full-scale production.

Video playback is available.

1970

Press Plant expansion completed

Installed a 1,000-ton double-action crankless press to enhance production capacity.

Video playback is available.

1972

Welding frame assembly plant expansion completed

Constructed a two-story assembly building to optimize floor space and implemented conveyor-based welding frame assembly.

1977

Started production of cabins for construction machinery

Started production of wheel loader cabs for Kawasaki Heavy Industries, Ltd., entering the construction machinery cab assembly business.

Video playback is available.

1977

3,000-ton press commenced operations

Constructed a new building and relocated the press machine from the Kawasaki Plant, enabling integrated production of long press-formed components.

Video playback is available.

1980

Started production of titan double cab for Mazda

Established an integrated production system from pressing to assembly, painting, and trimming by introducing a new body painting line.

1983

Introduced Spot Welding Robots

Introduced to automate welding and improve production efficiency.

1988

Prototype Plant completed

Engaged in prototyping for vehicle development.

1989

Completion ceremony held for Development and Welfare building

Built to expand design and development departments and integrate and modernize welfare facilities. A five-story reinforced concrete building.

Video playback is available.

1990

Started production of proceed marvie for Mazda

Jointly developed a full-scale SUV with Mazda and began mass production at the vehicle plant completed in April.

Video playback is available.

1993

Developed and launched miracle torch cleaner turbo

Developed by the prototype plant of the Design Section as part of business diversification. A device that automatically removes oxide film from welding wires during robotic welding.

Video playback is available.

1996

1,200-ton mechanical press commenced operations

1997

Started production of cabins for construction machinery that uses variant shaped steel pipes

Started production of the first cabin for construction machinery at Onomichi Plant.

1999

Draw bench equipment commenced operations

Introduced equipment to form variant shaped steel pipes from round pipes for full-scale mass production.

2000

Acquired ISO 9001 certification

2001

Transferred 80 employees to Kanto region

As part of business restructuring due to poor performance, implemented transfers of personnel to locations such as the Fujisawa Plant.

2002

Integrated Development and Production Departments for construction machinery cabins

To improve efficiency in the construction machinery business, consolidated the development and production functions for construction machinery cabins at Onomichi Plant.

2003

Began complete vehicle assembly of commercial trucks for Mazda

Following the manufacturing outsourcing agreement concluded with Mazda in October 2002, relocated assembly equipment and began production. Staff transferred from the Kanto region handled operations.

※動画再生できます。

2009

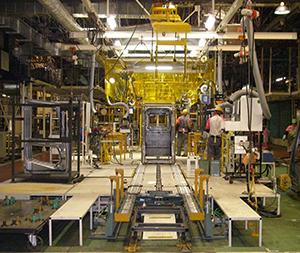

Started production of standard and compact radius type cabin for Kobelco Construction Machinery

Received new orders for hydraulic excavator cabs compliant with ROPS (Roll-Over Protective Structure). Began production on an assembly line featuring automation.

2016

Started production of roof and deck parts for Mazda MX-5(Roadster)

2018

Operations suspended due to heavy rain in Western Japan

Significant damage occurred to CKD parts for China and other items.

2020

Concluded complete vehicle assembly of Mazda Bongo Truck

Total production of complete Mazda Bongo trucks reached 211,960 units. The plant was transitioned into a dedicated construction machinery cab facility.

2022

Launched construction machinery cabins module business