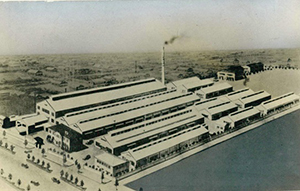

1937

Groundbreaking ceremony held for Head Office and Kawasaki Plant

Planned to construct a new plant in Shiohama-cho, Kawasaki City, Kanagawa Prefecture, to increase production capacity. Land acquisition was completed.

1937

Completion of Head Office and Kawasaki Plant; Headquarters functions and equipment relocated

The factory building was completed, and headquarters functions and equipment were relocated from the former head office in Oi, Ebara-gun, Tokyo.

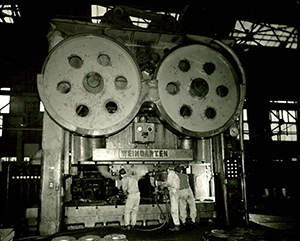

1941

Introduced 1,500-ton press manufactured in Germany by WEINGARTEN

Strengthened equipment to handle large volumes of military orders. Gained attention for its high precision.

1945

Partial damage due to air raid

While preparing for evacuation to Nagano Prefecture in April, the facility was hit by a U.S. air raid. Fortunately, an incendiary bomb penetrated the roof and embedded in the office floor without exploding.

1945

Production resumed

Following temporary dissolution after the end of the war in August, machines sent to Nagano were retrieved and production resumed. Products included bicycle parts, agricultural machinery parts, and consumer goods.

1954

Started production of axle cases for heavy-duty trucks

Built a new plant on the site of former tennis courts and sumo practice grounds behind the factory, introducing welding machines and other equipment. Started production with a team of 25 members.

1959

Expanded facilities including installation of 3,000-ton hydraulic press

Due to increased production, acquired adjacent land and carried out sequential expansion and renovation of buildings, including installation of additional press machines.

Video playback is available.

1962

Employee welfare hall completed

Constructed a three-story welfare hall to enhance employee welfare facilities amid company growth. The first floor had a clinic and lockers, the second floor had a large cafeteria, and the third floor had conference rooms.

1965

New head office building completed

To commemorate the 40th anniversary, constructed a five-story head office building. Held a completion celebration in June along with the anniversary ceremony.

Video playback is available.

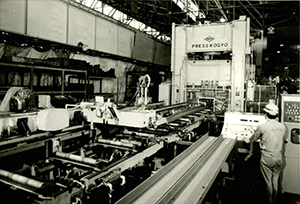

1966

Installed a 4,000-ton single-action crankless press machine

Installed single-action crankless press machine, the largest of its kind in Japan, to produce side members for large frames.

Video playback is available.

1972

Established frame assembly line for heavy-duty trucks

In response to the increasing size of trucks at the time, established a press line and automated the frame painting process from degreasing to primer application.

1976

Started production of stamped parking pallets

Formed the main body using a 4,000-ton press and completed welding assembly. Delivered to Nissan’s finished vehicle warehouse.

1976

Installed first NC-piercing machine

To improve drilling accuracy and reduce manual labor, our Tooling Department manufactured and installed the machine. Mainly used for machining frame cross members.

1980

Installed NC-piercing machine for frame side member web surfaces

Later, in November 1981, a second unit was installed, followed by an NC machining unit for flange surfaces in November 1984.

1984

Fully automated frame painting line became operational

Completed frames were transported by chain conveyor through electrostatic painting and touch-up processes, significantly improving the working environment.

1988

Second office building completed

Constructed a three-story reinforced concrete office building. The first floor had a clinic and security office, the second floor had the Kawasaki Plant’s administration, and the third floor had the Design and Overseas Business Departments.

1990

Started production of counterweight covers for construction machinery

Successfully began press forming covers for hydraulic excavator counterweights using a 3,000-ton hydraulic press. Started production for Hitachi Construction Machinery.

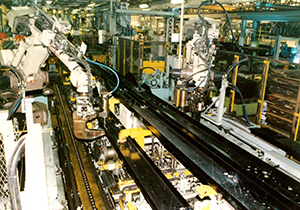

1992

Achieved non-changeover production on second axle line for heavy-duty trucks

Following the establishment of a cell production system for parts installation in 1989, implemented plasma cutting for round bars and automation of temporary ring fitting.

1993

Established dedicated line for super frames

Established a dedicated line for super frames (web-fastened large frames) for Mitsubishi Motors. An automatic riveting machine was installed in May.

2000

Acquired ISO 9001 certification

2000

Removed the 1,500-ton press manufactured by “WEINGARTEN”

Removed the 1,500-ton press manufactured by “WEINGARTEN,” which had been in operation for 59 years, due to aging. Production of railway vehicle components was discontinued.

2007

Transferred production of Isuzu large and medium truck frames to other plants and terminated operations

In response to the closure of Isuzu’s Kawasaki Plant, production of truck frames for Isuzu was transferred to the Fujisawa, Utsunomiya Plants as part of production restructuring.

2008

Began assembly of axle units for MFTBC trucks

Received transfer of assembly lines from Mitsubishi Fuso Truck and Bus Corporation (MFTBC), and started production axle units for heavy and light-duty trucks.

2013

Seismic reinforcement of Head Office; Welfare Building demolished

Due to seismic safety concerns, the welfare hall was dismantled and removed. Seismic reinforcement was carried out on the head office building, and facilities such as the cafeteria and lockers were relocated.

2024

New office and Welfare Building completed

As part of the 100th anniversary projects, a three-story office and welfare building was constructed on the site of the former welfare hall. The first floor had a clinic, the second floor had a large cafeteria, and the third floor had the Kawasaki Plant's administration.