1961

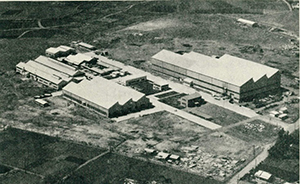

Groundbreaking ceremony held for Fujisawa Plant

Acquired factory land in Endo, Fujisawa City, Kanagawa Prefecture to expand production capacity in response to increased orders, and held a groundbreaking ceremony. In March, some functions were transferred from the Kawasaki Plant.

1961

Fujisawa Plant commenced operations

The wheel plant began operations ahead of schedule in July, and full operations started in October with the completion of the press plant. Phase 1 construction was completed in May 1962.

1965

Welfare Hall completed

To enhance employee welfare facilities amid company growth, a two-story welfare hall was constructed. The first floor had a clinic and lockers, while the second floor had a large cafeteria and conference rooms.

1965

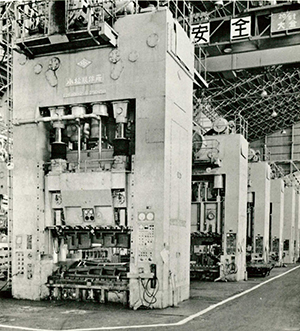

Installed two 600-ton crankless presses in Komatsu Press Line

Additionally, in August, an 800-ton press was added to the Clearing Press Line, further enhancing production capacity.

Video playback is available.

1967

Started production of Isuzu Unicab

Began producing 200 units per month. Entered the complete vehicle assembly business.

Video playback is available.

1969

Installed 4,000-ton single-action crankless press machie

This enabled integrated production of small truck frames for Isuzu at the Fujisawa Plant.

Video playback is available.

1970

Vehicle Plant completed; Started production of Nissan Patrol

Constructed a vehicle assembly plant with a monthly production capacity of 2,500 units and began producing the Nissan Patrol. Full-scale vehicle assembly operations commenced.

1973

Technical Research Center (Now R&D Building) completed

To enhance research and development, a two-story Technical Research Center was constructed on the plant premises.

1974

Frame assembly line completed

Installed two conveyor lines in a newly constructed building, integrating assembly of riveted and welded frames. Coordination with the painting line was also enhanced.

1979

New office building completed

Constructed a three-story office building to consolidate dispersed offices resulting from increased staffing.

1981

Started production of Isuzu’s first-generation Bighorn

Began producing a 4WD vehicle jointly developed with Isuzu Motors at the vehicle plant, with a planned monthly production of 2,000 units.

1983

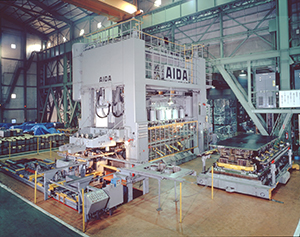

Installed 1,500-ton transfer press

Installed to improve productivity of suspension and panel components.

Video playback is available.

1983

Started production of plastic parts

Started production of console panels using a 200-ton injection molding machine introduced in 1981.

1985

Introduced cationic coating for frame painting

Implemented in response to the demand for improved corrosion resistance of chassis parts.

1990

Installed 2,500-ton and 800-ton injection molding machines

Established a plastic section and began producing interior parts for the Bighorn.

Video playback is available.

1991

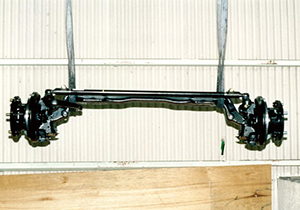

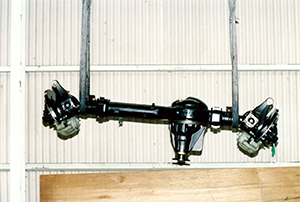

Started production of axle units for light-duty trucks

Started production of axle units for light-duty trucks for Nissan Atlas.

1991

Started production of Isuzu’s second-generation Bighorn

Following the final unit of the first generation going offline, began production of the long-wheelbase four-door model for the domestic market.

Video playback is available.

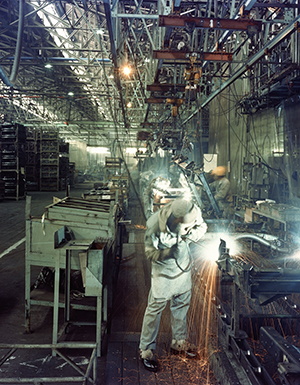

1993

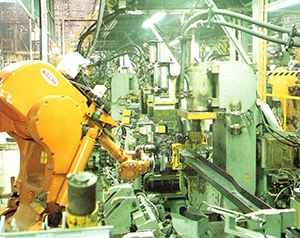

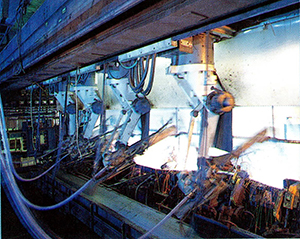

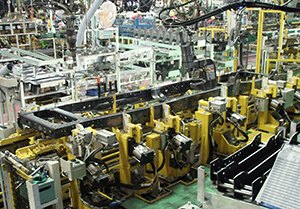

Commenced operations of the frame line for Isuzu’s fifth-generation ELF

Achieved significant streamlining and support for high-mix, low-volume production through automation of the welding line and side member drilling, as well as integration with the production control system.

1995

Acquired ISO 9001 certification

1996

Transferred production of the Bighorn back to Isuzu Motors

Due to declining production volumes, production was consolidated from parallel manufacturing by both companies to Isuzu Motors alone.

1997

Began pre-delivery Inspection (PDI) operations for GM Saturn

Following the launch of pre-delivery inspection operations for GM Saturn in 1997, a production system was established at the vehicle plant, covering everything from painting to final vehicle assembly.

Video playback is available.

2001

Vehicle Plant closed

Concluded 34 years of vehicle assembly operations in the Kanto area and dismantled the equipment. The site was planned to be repurposed as a base for core product manufacturing.

2002

Transferred development and production of construction machinery cabs to Onomichi Plant

To improve efficiency in the construction machinery business, the development and production functions for construction machinery cabs were transferred to the Onomichi Plant.

2006

Started production of riveted frames for Isuzu’s sixth-generation ELF

2007

Transferred production equipment for Isuzu heavy and medium-duty truck frames from Kawasaki Plant

In response to the closure of Isuzu’s Kawasaki Plant, production equipment for truck frames was transferred to the Fujisawa Plant as part of production restructuring.

2017

Parts electrodeposition coating line commenced operations

2020

Medium-duty axle welding and assembly line commenced operations

2023

Introduced shot blasting equipment for side member processing

Installed equipment to remove oxide film from the surface of steel materials. Improved corrosion resistance by enhancing the adhesion of the painting base.

2024

Equipment building completed

2024

New turbine compressor commenced operations

2024

Ground-breaking ceremony held for Welfare building